Maximising Equipment Longevity: Practical Tips for Catering Machinery Care Between Services

In the heart of every thriving kitchen, the hum of catering machinery is the soundtrack of efficiency. To ensure these culinary workhorses continue to perform at their best between professional servicing intervals, adopting a proactive approach to care is paramount. Here are practical tips that catering businesses can implement to safeguard their equipment, enhance longevity, and maintain peak performance.

1. Routine Cleaning:

Problem Avoidance:

Accumulated grease, grime, and food particles not only compromise hygiene but also contribute to machinery malfunctions.

Tip:

Implement a regular cleaning schedule for all equipment. Focus on areas prone to buildup, such as grills, ovens, and ventilation systems.

Use manufacturer-approved cleaning agents to avoid damage to sensitive components.

2. Proper Usage Practices:

Problem Avoidance:

Misuse or improper handling of machinery can accelerate wear and lead to premature breakdowns.

Tip:

Train kitchen staff on the correct operation of each piece of equipment. Ensure they understand load capacities, usage limitations, and safety protocols.

Display clear usage guidelines near equipment to serve as a quick reference for staff.

3. Temperature Control Maintenance:

Problem Avoidance:

Fluctuations in temperature can compromise food safety and strain the efficiency of refrigeration or heating equipment.

Tip:

Regularly calibrate temperature controls to ensure accurate readings.

Check and replace thermostat batteries as needed to maintain consistent performance.

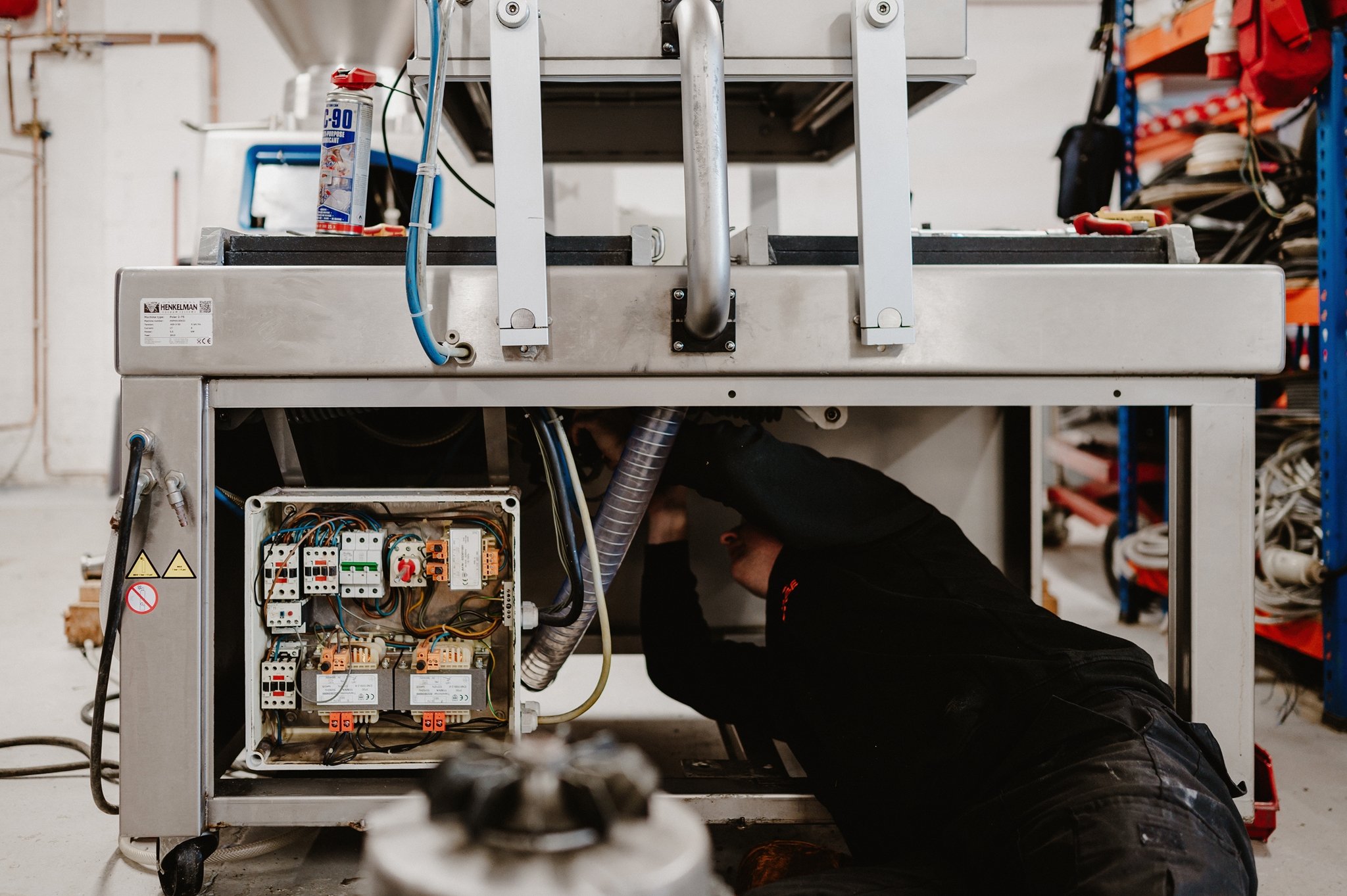

4. Visual Inspections:

Problem Avoidance:

Small issues left unaddressed can snowball into major problems over time.

Tip:

Encourage routine visual inspections by kitchen staff. Provide a checklist for common issues like leaks, unusual noises, or visible wear.

Establish a reporting system for staff to communicate potential issues promptly.

5. Prompt Repairs of Minor Issues:

Problem Avoidance:

Ignoring minor issues can lead to more extensive damage and costly repairs down the line.

Tip:

Empower staff to report and, when possible, address minor issues immediately. This could include tightening loose components, fixing minor leaks, or replacing worn-out seals.

Keep a small toolkit on hand for quick fixes that don't require professional intervention.

6. Documented Maintenance Records:

Problem Avoidance:

Lack of documentation can lead to oversights in servicing schedules and missed opportunities for preventive care.

Tip:

Maintain a comprehensive log of all equipment maintenance and repairs.

Include dates of last servicing, issues addressed, and any recommendations from professional technicians.

Summary

Caring for catering machinery between professional services is not just a task; it's a strategy for prolonged efficiency and reliability. By incorporating these practical tips into daily operations, catering businesses can create a culture of proactive equipment care. This not only minimizes the risk of unexpected breakdowns but also contributes to cost savings, an extended equipment lifespan, and a kitchen that operates with precision and confidence. In the world of culinary excellence, where every detail matters, the longevity of your machinery is a recipe for success.